-

E-mail

guhaixin0724@gmail.com

E-mail

guhaixin0724@gmail.com

-

Call Us

008613683147042

Call Us

008613683147042

E-mail

guhaixin0724@gmail.com

E-mail

guhaixin0724@gmail.com

Call Us

008613683147042

Call Us

008613683147042

2025-03-31 Views: 918

Warm Tip: If you want to know more information, like quotation, products, solutions, etc., please Click here ,and contact us online.

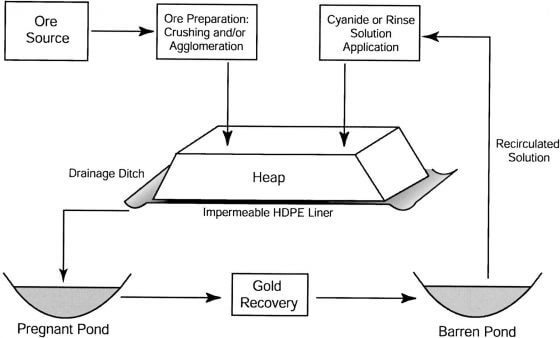

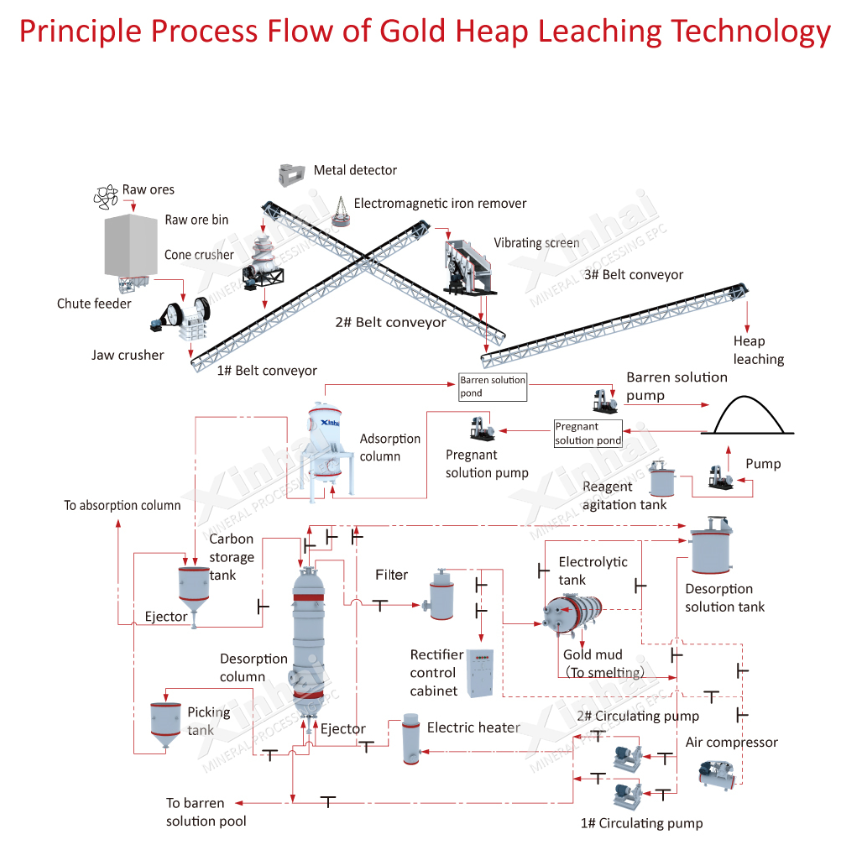

Heap leaching is a hydrometallurgical technique that extracts target metals (e.g., gold, copper, uranium) from low-grade ores by dissolving them with chemical leaching solutions. The core principle involves stacking crushed ore on an impermeable base, spraying it with leaching agents (e.g., sodium cyanide or eco-friendly CNLITE reagents), and collecting metal-laden solutions for recovery via adsorption or displacement. The leaching solution is recycled to enhance resource efficiency.

Heap leaching involves six key stages:

Ore Preparation

Crushing ore to 30–50mm particles or pelletizing fine particles to improve permeability. Pre-treatment (e.g., agglomeration) is required if clay content exceeds 5%.

Heap Pad Construction

Sites are built near mining areas on gentle slopes (5–15° natural gradient). The base is compacted, lined with geomembranes, and surrounded by drainage ditches to prevent contamination.

Ore Stacking

Layered stacking (3–9m height, up to 46m for large heaps) ensures uniform permeability and minimizes particle segregation.

Leaching Solution Preparation

Alkaline solutions (0.025–0.1% sodium cyanide or CNLITE) are used. pH is maintained at 9.5–11, with lime pretreatment to neutralize acidic impurities.

Solution Application and Collection

Solutions are sprayed via drip irrigation or sprinklers. Pregnant solution flows into collection ponds, while barren solution is recycled.

Metal Recovery

Gold is recovered via activated carbon adsorption or zinc powder displacement. Loaded carbon undergoes desorption and electrolysis to produce gold mud.

Ore Types

Oxidized Ores: Porous, fractured ores (e.g., quartz veins, porphyry gold) with fine-grained gold in limonite or quartz.

Low-Grade Ores: Gold grades of 1.0–3.0g/t, low sulfide content, and high oxidation (e.g., iron cap or carbonate ores).

Tailings/Waste Rock: Reprocessing of low-grade waste from mining operations.

Scale Flexibility

Suitable for small-scale (hundreds of tons) to large-scale operations (hundreds of thousands of tons). Example: A 100,000-ton heap leaching trial at Xinjiang’s Sarbulak Gold Mine.

Advantages

Cost-Effective: Low capital and operating costs, ideal for low-grade ores.

Eco-Friendly: Reduced emissions vs. smelting; closed-loop solution recycling. CNLITE minimizes toxicity risks.

Adaptability: Scalable and suitable for remote or fragmented deposits.

Limitations

Long Cycle: Leaching may take months to years (e.g., nickel laterites require ~2 years).

Environmental Risks: Cyanide leakage risks necessitate strict containment.

Climate Sensitivity: Rainfall or low temperatures reduce efficiency; requires flood/thermal controls.

| Criteria | Sodium Cyanide | CNLITE Agent |

|---|---|---|

| Toxicity | Highly toxic (LD₅₀=6.4mg/kg) | Low toxicity, environmentally safe |

| Waste Disposal | Classified as hazardous (HW33) | Treated as general industrial waste |

| Applicability | Prone to sulfide/carbon interference | Resists interference, suits complex ores |

| Leaching Rate | High (65–85%) | Comparable (76% in trials) |

| Environmental Cost | High (requires wastewater treatment) | Low (simplified waste management) |

Site Selection

Avoid unstable geology (landslides, karst) and proximity to water sources. Base compaction ≥0.93 density.

Liner System

Double-layer HDPE geomembranes with ultrasonic seam testing. Anchor trenches ≥800mm×800mm.

Solution Management

Separate ponds for pregnant/barren solutions, sized for maximum rainfall. Channels slope ≥2% for gravity flow.

Monitoring

Groundwater monitoring wells (1 upstream, 3 downstream) for cyanide detection. Post-leaching rinsing (pH 8–10) protects liners.

China: Shuangwang Gold Mine (Shaanxi) and Sarbulak Gold Mine (Xinjiang) achieved 65–70% leaching rates in 10,000-ton trials.

CNLITE Application: A 300t/day gold mine in Mongolia achieved 76% leaching with safe tailings storage, meeting “Green Mine” standards.

Smart Systems: Sensor-controlled sprayers optimize leaching efficiency.

Bioleaching: Microbes reduce chemical usage.

Modular Pads: Lower infrastructure costs for remote small-scale mines.

Heap leaching remains pivotal for low-grade ore exploitation, balancing economy and adaptability, though ongoing environmental safeguards are critical for sustainable development. If you have any questions, come to us at anytime!

No. 188, Xinhai Street, high-tech Industrial Park, Fushan District, Yantai, Shandong, China.

Please leave your message here! We will send detail technical info and quotation to you!