-

E-mail

guhaixin0724@gmail.com

E-mail

guhaixin0724@gmail.com

-

Call Us

008613683147042

Call Us

008613683147042

E-mail

guhaixin0724@gmail.com

E-mail

guhaixin0724@gmail.com

Call Us

008613683147042

Call Us

008613683147042

Home

Guides

Leaching Reagent Guide

Heap Leaching Test Using Environmental-friendly Gold Leaching Reagent for Sodium Cyanide Replacement

Home

Guides

Leaching Reagent Guide

Heap Leaching Test Using Environmental-friendly Gold Leaching Reagent for Sodium Cyanide Replacement

2020-03-22 Views: 4965

Warm Tip: If you want to know more information, like quotation, products, solutions, etc., please Click here ,and contact us online.

The environmental-friendly gold leaching reagent has a series of advantages including low toxicity, simple use, and high gold leaching rate when replacing sodium cyanide under conventional alkaline conditions. A certain mining company uses sodium cyanide as gold reagent in its heap leaching plant. In order to verify the feasibility of using environmental-friendly gold leaching reagent to replace sodium cyanide in heap leaching process, the company conducted a heap leaching industrial production test. This test shows that using environmental-friendly gold leaching reagent present better index than using sodium cyanide in terms of chemical consumption, leaching cost, and final gold leaching rate. Let's take a look at its industrial production test process:

Before carrying out the industrial production test, first select 30kg ore sample (the properties of the ore are the same as those in the on-site heap leaching production) for a small-scale test to determine the leaching effect of environmental-friendly gold leaching reagent. The gold recovery rate was 85.2%, which shows that the environmental-friendly gold leaching reagent has an ideal leaching effect and can be applied to industrial production tests of heap leaching.

The industrial test site is selected near the broken ore stacking site, with a flat area of about 50m*18m and a stackable height of about 3.5m, which has an irregular trapezoidal shape. There is a 6m*6m*2m pregnant liquid pool and a 6m*6Ill*2m lean liquid pool.

(1) The environmental-friendly gold leaching reagent consumed is 334kg, and gold leaching reagent required per ton of ore processed is 73 grams;

(2) The total CaO consumed is 14 tons, namely 3kg/t;

(3) Consumption of activated carbon: column I is about 768kg, and column II is about 500kg;

(4) Spray time: sampling and monitoring is conducted once a day under continuous operation;

(5) Spray intensity: the spray intensity is 15m³/h, and the spray water volume is about 360m³/d;

(6) Adsorption while spraying, the period is 30 days.

Use the same heap leaching process as the mining company's current production for open-air spraying operations. The specific steps of heap leaching gold process are as follows:

(1) Adopt a double-layer polyethylene color stripe cloth with a layer of polyethylene film structure in between. Carefully lay the heap leaching bottom pad, piled up ore for 4563t at a time, which is about 3m high, add 14t lime to mix and overturn the pile, then install the spray device well;

(2) Add 200kg environmental-friendly gold leaching reagent to the lean liquid pool and start spraying;

(3) The return liquid of the noble liquid flows into the noble liquid pool, and it is adsorbed with carbon after being clarified; the lean liquid continues to be circulated and sprayed, and the spraying process is appropriately supplemented according to the mass fraction of the environmental-friendly gold leaching reagent;

(4) The initial mass fraction of the environmental-friendly gold leaching reagent is 0.028%. In the heap leaching operation, it is necessary to ensure that its mass fraction is maintained in an appropriate range. Sampling is tracked daily during heap leaching. On the second day of spraying, the mass concentration of the noble liquid reached a maximum of 4.75 g/m with a good adsorption effect. The mass concentration of the lean liquid remained below 0.02 g/nq, and the adsorption rate reached over 98%. At the beginning of spraying, the pH value is low, generally 8-9; after three days of spraying, the pH value increases to 10-11.5;

(5) When the spraying reaches the 16th day, the mass concentration of gold is below 0.06g/m, the spraying is suspended. At this time, it is necessary to turn over the pile and reinstall the spray device, and add an appropriate amount of environmental-friendly gold leaching reagent;

(6) By the 30th day, when the mass concentration of gold drops below 0.03g / m, take out the gold-loaded carbon, and measure the moisture content of gold-loaded carbon, desorbed lean carbon and leaching slag and analysis of gold-loaded carbon grade;

(7) Finally, smelt gold-loaded carbon.

The industrial test results are: heap leaching raw ore gold grade 1.16g/t, using environmental-friendly gold leaching reagent dosage 73g/t; leaching slag gold grade 0.18g/t, according to the theoretical leaching slag leaching rate of 84.48%, according to gold-loaded carbon metal content The theoretical recovery rate is 83.12%; the actual recovered metal is 4042.61g, and the actual recovery rate is 78.74% (lower than the theoretical value and small test value may be affected by factors such as test deviation, test condition differences, and ore particle size differences).

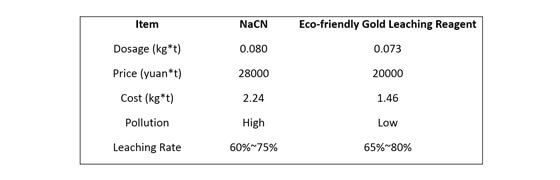

The contrastive analysis of industrial heap leaching using environmental-friendly gold leaching reagent and sodium cyanide are shown in the figure below. Compared with sodium cyanide, the environmental-friendly gold leaching reagent has greatly improved in terms of chemical consumption, cost and toxicity, which not only reducing the production cost, but also reducing environmental pollution.

The above industrial test practice proves that it is technically feasible to replace the sodium cyanide with an environmental-friendly gold leaching reagent in the gold heap leaching production because of its good social and economic benefits. The technical data, indicators and operating conditions obtained from industrial tests have laid the foundation for the promotion and application of environmental-friendly gold leaching reagent in production. The environmental-friendly gold leaching reagent used in the heap leaching method has wide applicability to similar gold mines, thus having great promotion significance. It is recommended that mine owners who plan to build green mines should find regular environmental-friendly gold leaching reagent manufacturers, design a reasonable ore dressing solution through scientific experiments, and maximize the overall benefits.

No. 188, Xinhai Street, high-tech Industrial Park, Fushan District, Yantai, Shandong, China.

Please leave your message here! We will send detail technical info and quotation to you!