-

E-mail

xhcnlite@ytxinhai.com

E-mail

xhcnlite@ytxinhai.com

-

Call Us

008615901320633

Call Us

008615901320633

E-mail

xhcnlite@ytxinhai.com

E-mail

xhcnlite@ytxinhai.com

Call Us

008615901320633

Call Us

008615901320633

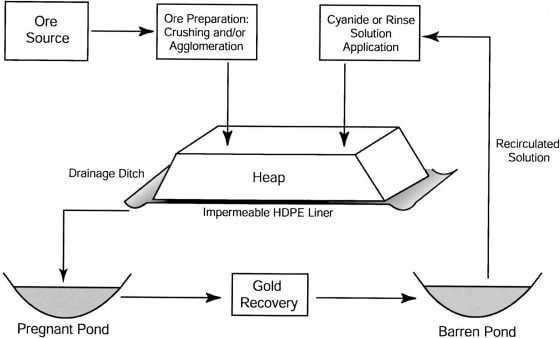

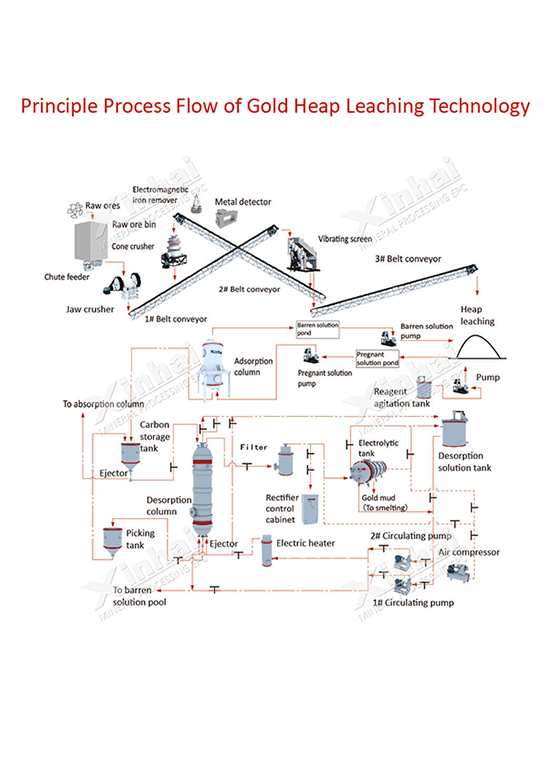

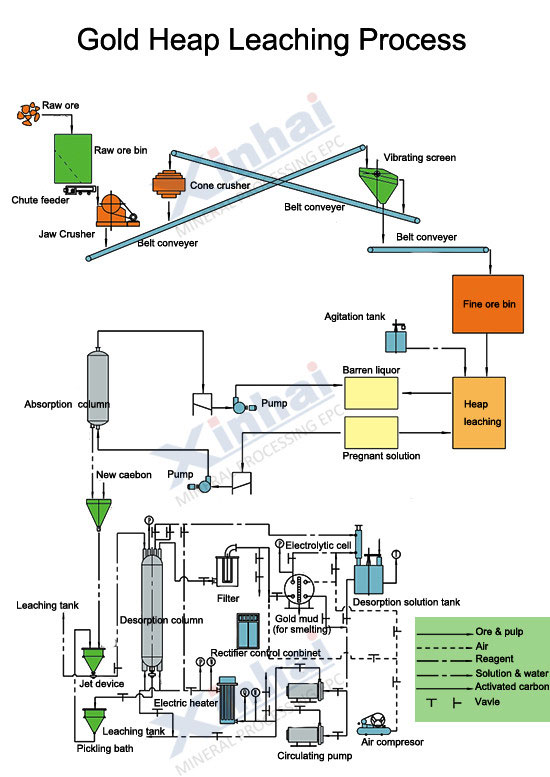

【Principle】Heap leaching (HL) is a flexible and economic gold ore processing method used to extract gold from low-grade gold ores. In this process, ore is firstly crushed to fine particles. By spraying leaching solution to the large piles, the gold-containing solution is leached. Then used the gold processing method of carbon adsorption, zinc powder displacement device and so on to separate gold from the liquid.

【Process】

【Application】Low-grade gold ore; Small-scale gold ore

Gold heap leaching process means transfer the raw ore to the prepared yard, or directly stock on the waste rock or low-grade ore, then use cyanide leaching chemical or CNLITE eco-friendly gold dressing agent to spray or infiltrate, and the ore reacts with the cyanide leaching liquid. After several recycling of leaching liquid and repeat spray, the leaching liquid can be collected. Then, treating leaching liquid by the activated carbon or metal zinc method and the barren solution returns to heap leaching operation for reuse.

The raw ore is crushed into fine particles (30-50mm) by using jaw crusher or cone crusher, then will be heap leaching directly; or pelletization (fine particles are pelletized into bigger lumps ), then piled by forklift.

Generally, heap leaching site is the gentle slope hills (natural grade 5-15 ˚) that nears the mining site. Removing weed sand lose material firstly, and then consolidate it as the foundation with 5 ˚gradient. The sides are high and the middle is low, which makes leach liquid flow into the stationary tank easily. The yard is covered with geomembrane to prevent leakage. Around the storage yard, a 0.4-meter ridge of soil shall be built as a ditch to prevent the rainwater from flowing into the yard. Besides, build a 0.3-meter-thick of lean ore before stacking the ore.

Then the large piles will be sprayed by the leaching solutions, through which the gold-containing solution will be leached from the piles. The pregnant liquid will flow into pregnant solution pool. Then used the gold ore processing method of adsorption of activated carbon, zinc powder displacement device and so on to separate gold from the liquid. The tail liquid will be recycled.

Gold heap leaching process has low production cost and it can be put into production quickly. In addition, the scale of heap leaching is more flexible, even more than tens of thousands of tons.

Desorption Elctrosysis System

Leaching Agitation Tank

CNLITE Leaching Reagent

Jaw Crusher

Belt Conveyor

Wear-resistant slurry pump

Auto Centering Vibrating Screen

Washing Thickener

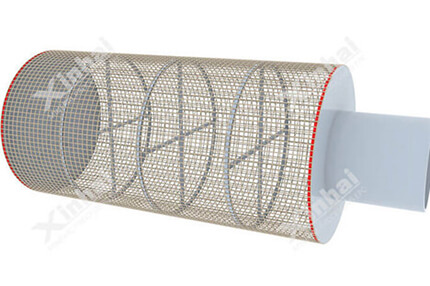

Carbon Screen

Air Lifter

Chute Feeder

Zinc Powder Displacement Device

The gold ore in the heap leaching project in Suriname is hard to separate, but using CNLITE gold leaching reagent, it reaches a relatively ideal result.

The project leader of 300 tpd gold mine heap leaching project in Mongolia tried CNLITE gold leaching reagent and got great result, thus reached a long-term cooperative relationship with us.

Please leave your message here! We will send detail technical info and quotation to you!