-

E-mail

guhaixin0724@gmail.com

E-mail

guhaixin0724@gmail.com

-

Call Us

008613683147042

Call Us

008613683147042

E-mail

guhaixin0724@gmail.com

E-mail

guhaixin0724@gmail.com

Call Us

008613683147042

Call Us

008613683147042

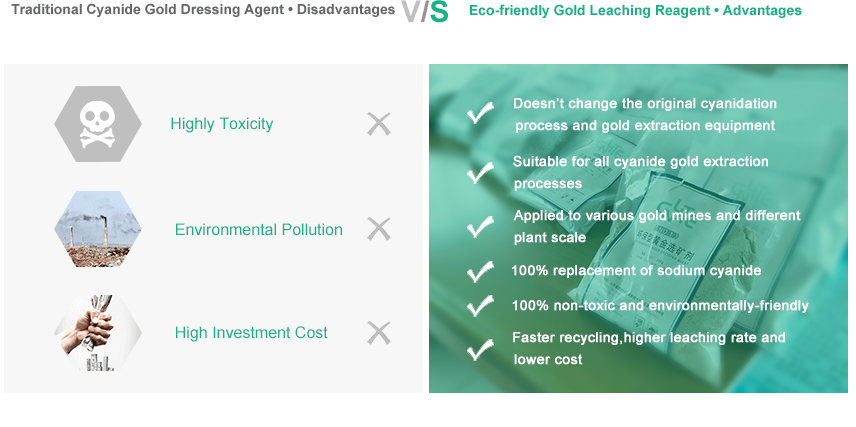

According to statistics, more than 80% gold mines in the world use gold cyanidation process, while 85% of them use sodium cyanide to extract gold. However, cyanide is a highly poisonous and dangerous chemical, and any accidents in transportation storage and usage will resuilt in serious consequences. Therefore, many countries and states have explicitly banned or restricted the use of sodium cyanide in gold extraction and the global gold extraction industry urgently needs an environmental gold extraction agent that can completely replace cyanide.

CNLITE eco-friendly gold leaching reagent is a kind of leaching reagent that can replace sodium cyanide without changing the original equipment and cyanide process. It can be used directly for gold ore beneficiation and refining, commonly in the gold heap leaching process, pool leaching process, CIP, CIL, etc...

100% Environmental-friendly

High Leaching Rate

Low-toxicity

Easy to Transport

100% Replacement of Sodium Cyanide

Stable Performance

Faster Recycling

Suitable for All Gold Cyanidation Plants

Gold Leaching Chemicals (Large Package)

Gold Leaching Chemical (Test Sample)

Gold Leaching Chemical (Application)

【Principle】

Gold CIL process (carbon in leach) refers to add activated carbon to the pulp, leach and adsorb gold in the same time. It is an effective way to recover gold, and can reach 99% recovery rate.

【Process】

1. Crushing and screening

2. Grinding and classification

3. Agitation

4. Cyanide leaching and adsorption

5. Desorption electrowinning

6. Purified ingot

【Cases】

Gold CIL Plant in China

Gold CIL Plant in Sudan

Gold CIL Plant in Zimbabwe

【Principle】

Gold CIP (carbon in pulp) process refers to an unfiltered cyanide carbon slurry process that uses activated carbon to directly adsorb and recover gold from cyanide ore pulp. Generally, carbon adsorption is performed after cyanide leaching is completed.

【Process】

1. Crushing and screening

2. Grinding and classification

3. Agitation and cyanide leaching

4. Carbon adsorption

5. Desorption electrowinning

6. Purified ingot

【Cases】

Gold CIP Plant in Ghana

Gold CIP Plant in Malaysia

Gold CIP Plant in Tanzania

【Principle】

Gold heap leaching refers to pile up low-grade gold ore or flotation tailings on the bottom mat material, and then spray it through the sodium cyanide solution to dissolve the gold in the ore to form a gold-containing pregant liquid and finally refine to recover gold.

【Process】

1. Crushing and screening

2. Set heap leaching site

3. Heap spraying and cyanide leaching

4. Carbon adsorption

5. Zinc powder displacement device

【Cases】

Gold Heap Leaching Plant in South Africa

Gold Heap Leaching Plant in Suriname

Gold Heap Leaching Plant in Zimbabwe

【Principle】

Gold heap leaching refers to pile up low-grade gold ore or flotation tailings on the bottom mat material, and then spray it through the sodium cyanide solution to dissolve the gold in the ore to form a gold-containing pregant liquid and finally refine to recover gold.

【Process】

1. Crushing and screening

2. Grinding and classification

3. Pump slurry into vat or tank

4. Agitation and cyanide leaching

5. Carbon adsorption

6. Zinc powder displacement device

【Cases】

Gold Heap Leaching Plant in South Africa

Gold Heap Leaching Plant in Suriname

Gold Heap Leaching Plant in Zimbabwe

Desorption Electrolysis System

Elution Column

Leaching Tank

Washing Thickener

Zinc Powder Displacement Device

Agitation Tank for Chemical

Carbon Screen

Air Lifter

Please leave your message here! We will send detail technical info and quotation to you!